EXPERTISE

Electrical & Instrumentation Engineering

Reliability and Transparency in Maritime Engineering

Load Charts & Power Distribution

Design of extensive Electrical System with Power Generation and Power distribution analysis according to vessel configuration, safety and reliability. This involves the Selection of the appropriate large drivers, picking the correct generation configuration (including prime, essential and emergency sources), configuring the electrical distribution system and deciding the various details of the electrical distribution, control and safety system.

Load Cases & Analysis

The complete load analysis of electrical loads considering various load cases. Sizing of Prime source like Generators, Essential loads and Emergency source of power (Emergency Diesel Generator), Sizing of Medium voltage and low voltage power distribution transformers.

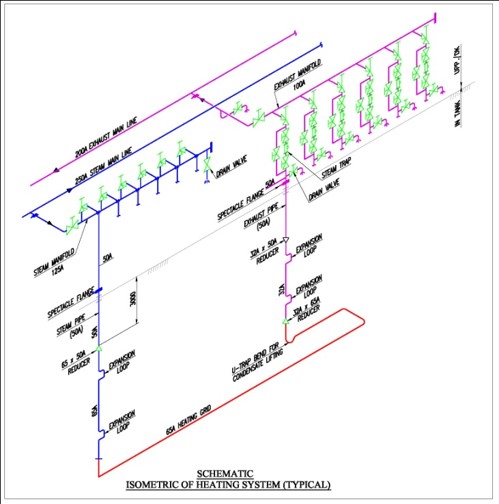

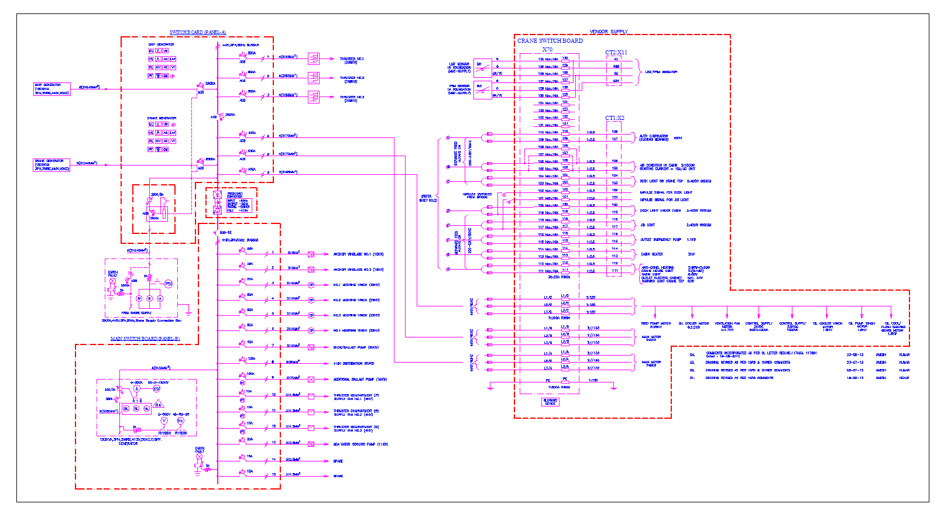

Single Line Diagrams

Preparation of Single Line Diagram for complete Power distribution system, Switchgear sizing, Cable sizing, Battery sizing as per IEC standards, API regulations and class rules. Establishing the philosophy for protection, co-ordination and safety of the power generation and distribution system.

Analysis

Following studies carried out using well known software like ETAP (Electrical Transient Analyser Program) for safe and optimized electrical system:

- Load Flow Analysis

- Short Circuit study

- Motor Starting Study

- Electrical Protective devices co-ordination study

- Transient Stability study

- Protection against System faults and abnormal conditions

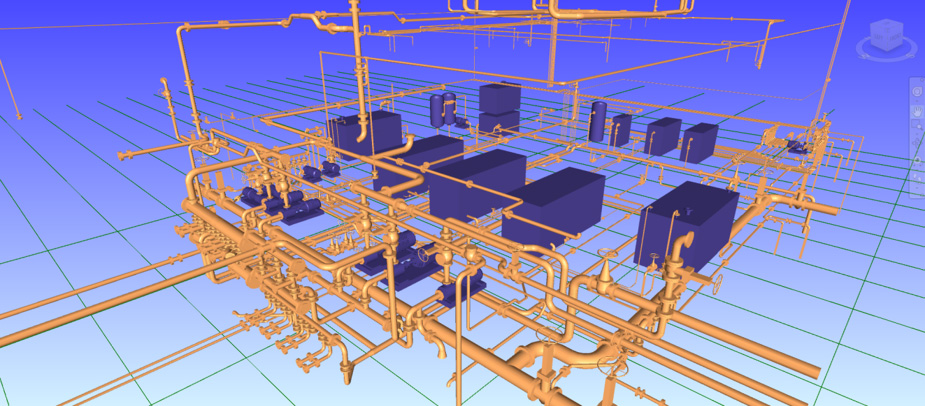

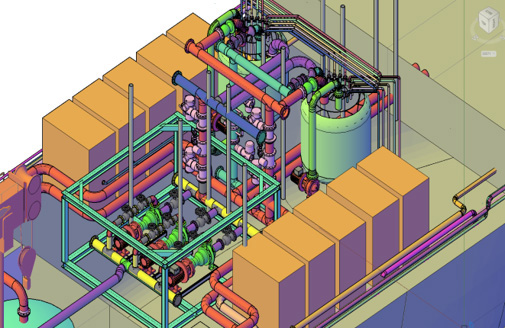

Layouts

Complete Switchboard room layout and arrangement considering the power distribution, different voltage levels, operational flexibility and ergonomics. Battery and UPS room layout design. Layout Engineering of Electrical equipments considering the power distribution system, operational requirements, hazardous area applications, safety etc.

Sizing

Sizing of uninterruptible power supply (UPS) for critical services and Safety systems. Direct current supplies for specialized equipments. Design of automation systems covering process control and safety systems, including emergency shutdown (ESD) and fire and gas (F&G) detection and control.

Hazardous Areas

Deciding and categorizing of the hazardous zoning and preparation of hazardous area plan for selection of correct type of equipment’s/instruments to suit the zone requirements. Selection of correct Ex. rating and temperature class of the equipment’s to be installed in hazardous environment.

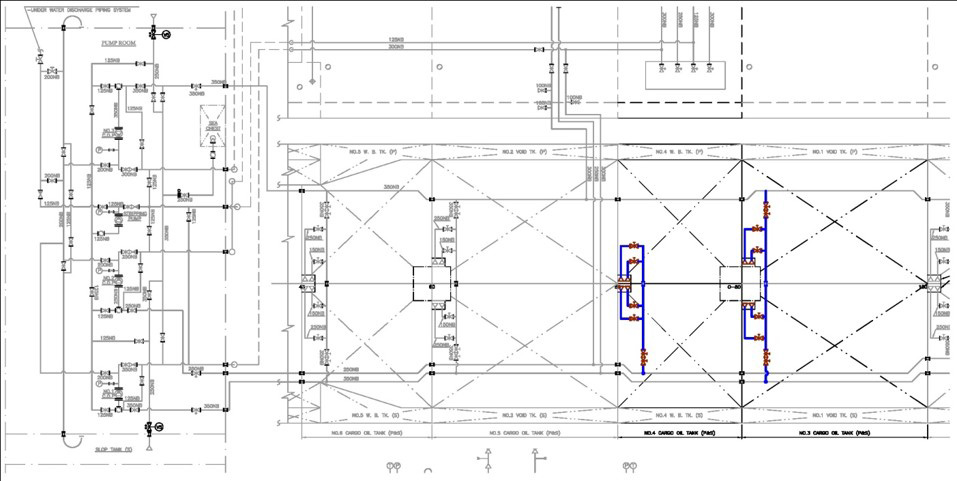

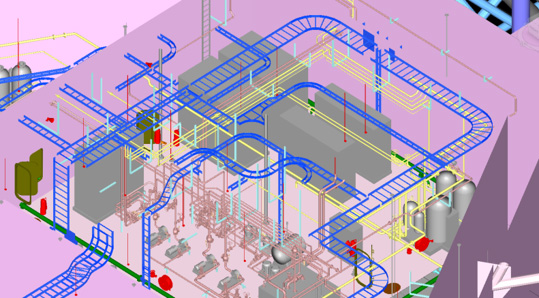

Cable Tray Routing

Design and engineering of auxiliaries like cable tray routing for Topside, hull and living quarters. Earthing system design and layout, MCT block design and arrangements, Normal, Emergency and Critical Lighting System and layout.

Procurement Support

Procurement engineering including preparation of RFQ, Vendor offer evaluation as per tender requirements and regulatory authorities requirements, Technical liaising/negotiations with vendors for optimized solutions, Preparation of technical evaluation documents and purchase specifications.

Data Collection

In case of conversion, Pre-engineering survey can be carried out for all the equipments on board the vessel. This engineering activity is very critical in order to assess the condition of equipments which can be retained and identify the equipments to be replaced. Also identification of modifications required to be done on the existing system to suit the requirements of conversion.

Instrumentation Engineering

- Development of control philosophy and design of Overall System architecture as per process requirements.

- Development of Critical Signal, co-ordination and communication philosophy and Emergency Shutdown system philosophy

- Interface engineering between Centralized control system and various packages in topside and Hull for data and signal transfer.

- Preparation of control room layout considering the overall system architecture, operators comfort, access considerations, maintenance and ergonomics.

- Design and Engineering of complete F&G system (both addressable and non-addressable type) as per API Standards and equipment layout. Preparation of F&G System layout with coverage area marking for each detector. Preparation of F&G block diagram and Single line diagram. Preparation of I/O counts and O/L list and Cause and effect matrix for selection of appropriate protection method.

- Design and engineering of communication system including PAGA System, internal communication system, alarm and signal system as per overall layout and regulatory requirements. Preparation of PAGA layout, looping and zone diagram for full coverage of all spaces, Single line diagram for PAGA System and Intercom system.

- Selection of Radio communication and navigation equipments as per statutory requirements. Preparation of detailed specification of Radio communication and navigation equipments. Radio room layout considering the operational aspect and functional requirements. Arrangement of antennas for radio equipments to isolate the signals of different radio equipments from each other and to obtain error free signals and readings of equipments.

- Design and engineering of Tank Gauging system which includes selection of correct type of level transmitter for various applications, preparation of specification of major components of Tank Gauging system like Level Transmitters, Controller etc. Selection of correct location of level transmitter considering the overall dimensions of tank and also to minimize the effect of heel and trim of the hull.

- Load Charts & Power Distribution

- Load Cases & Analysis

- Single Line Diagrams

- Analysis

- Layouts

- Sizing

- Hazardous Areas

- Cable Tray Routing

- Procurement Support

- Data Collection